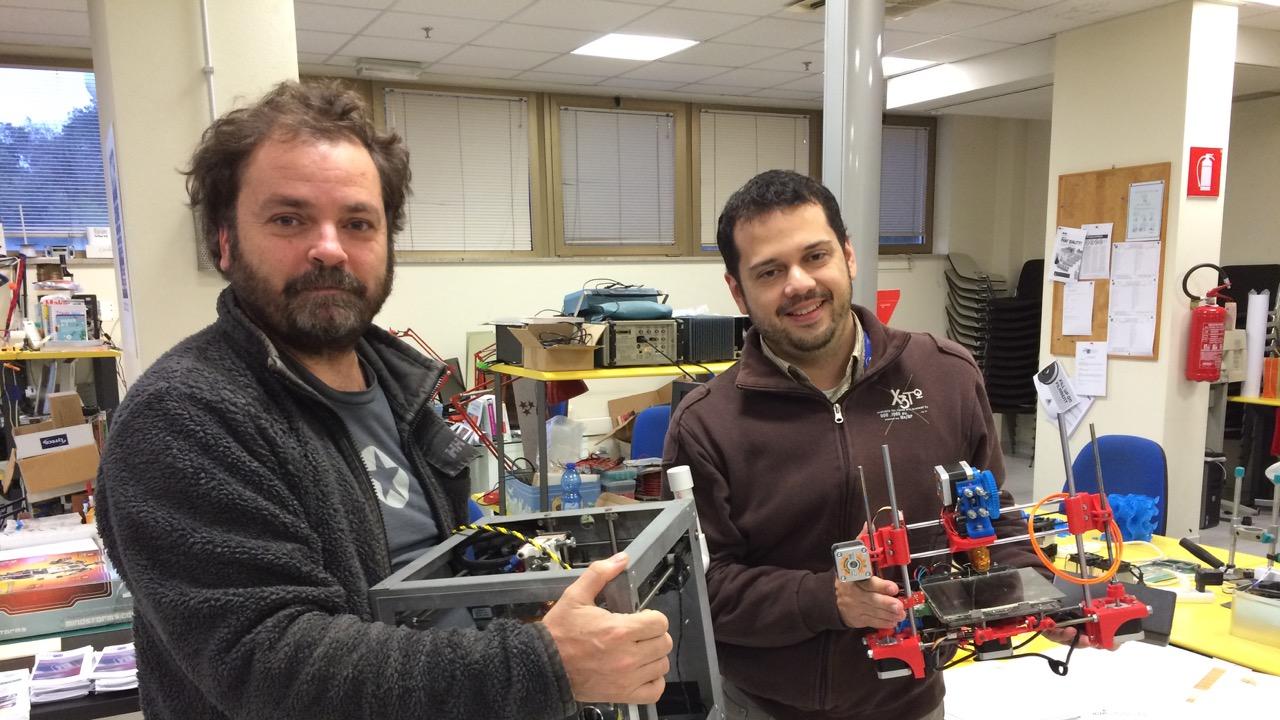

Printing at the University of Cartagena, Colombia, will have a new dimension. On 25 November 2014, ICTP's Scientific Fabrication Laboratory (SciFabLab) donated two 3D printers to the University's Applied Mathematics Institute. Head of the Institute Javier Antonio Montoya was at ICTP for a scientific visit and to carry out a project with the SciFabLab, and he will be taking the two printers back with him to Cartagena.

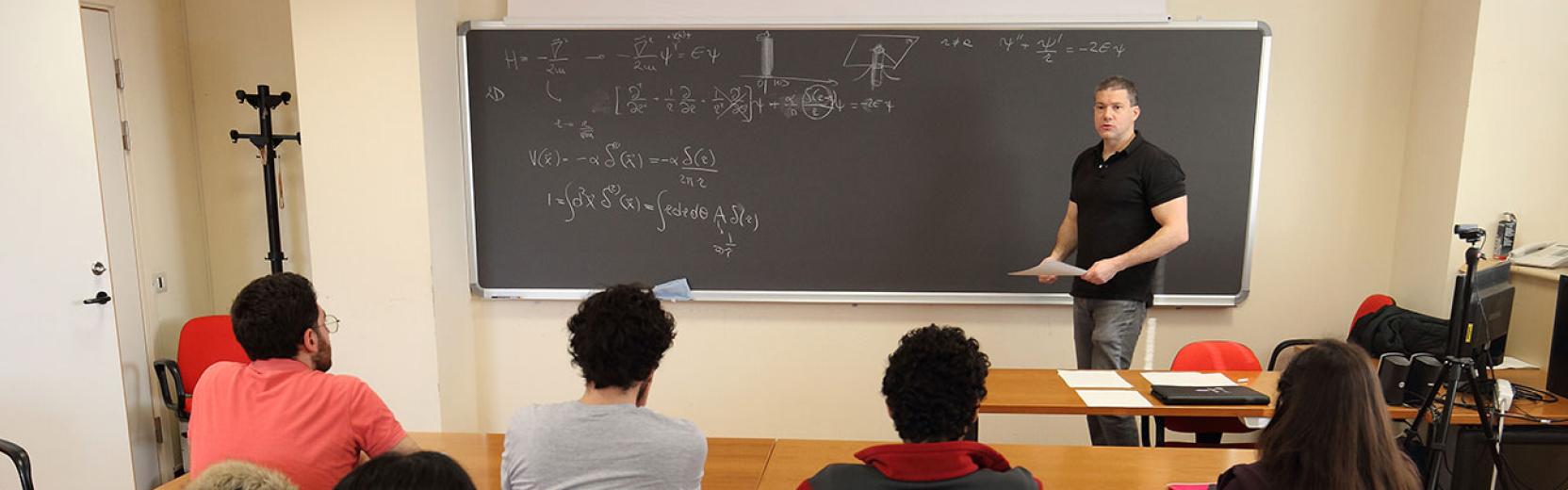

One goal is to use the low-cost, desktop 3D printers for producing (or printing) mathematical objects that would otherwise be difficult to visualize. "Students can see the shape of such objects in a more intuitive manner so that helps to improve the understanding of certain mathematical functions," says Montoya. ICTP researchers at SciFabLab have already worked together to produce 17 mathematical objects using new and affordable 3D printing technologies (see their paper for more details). Montoya says that the two printers ICTP has donated are of different styles; while one will be mainly used to print objects, the other will be used to teach students the basic principles behind 3D printing technology.

Montoya not only wants to incorporate the 3D printers into teaching courses, but also hopes to use them to continue the research that he began at the SciFabLab. Montoya and ICTP researchers are trying to produce conductive plastic filaments in order to be able to print circuits. A condensed matter physicist by training, Montoya had some ideas regarding using ionic elements inside the plastic filament. But before printing these conductive filaments, the researchers needed to find a scalable solution to produce low-cost plastic filaments. The commercial options available (which involve the use of plastic pellets) are not cost-effective. So, Montoya, along with ICTP researchers from the SciFabLab, collected used plastic bottle caps from ICTP cafeterias. They were able to demonstrate that plastic from bottle caps can be converted to plastic filaments used in 3D printing.

"Now that we have an easy and cheap way to produce plastic filaments, the next step would be to think about what we need to mix with it to make it conductive," says Montoya. He explains that the conductor will be a polymer matrix that will contain ions that can move. The applications for such conductive filaments can be numerous. "They can find use as sensors, to connect circuits together, and to produce low cost wearable materials that can pass signals and data. But these are just a few examples," he says.

To read more about how the plastic filaments were produced from bottle caps, visit ICTP's SciFabLab blog